Imagine launching your POD shop with a design that looks incredible online — only for your first customer to leave a one-star review because the print cracked after one wash. That’s the real truth of print on demand: success isn’t just about the design. It’s about choosing the right print on demand materials and pairing the best fabrics with the right printing method.

This guide covers the essentials: fabrics, types of t-shirt materials, printing methods, cost breakdowns, and the mistakes that ruin too many beginners. By the end, you’ll know how to avoid wasted money — and how to create products customers actually want to wear.

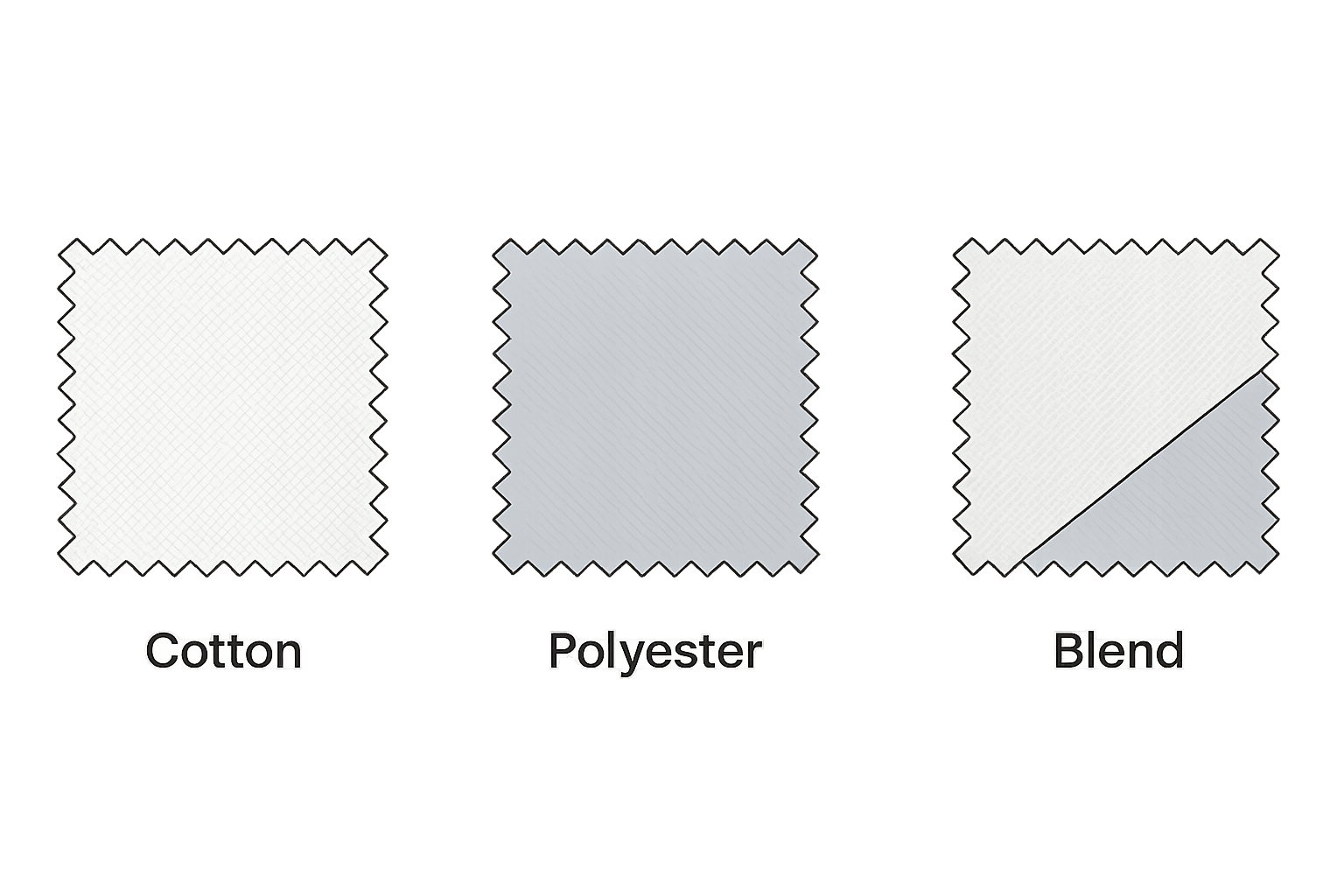

Understanding Fabrics and Materials

Cotton

Cotton is the classic T-shirt fabric: soft, breathable, and comfortable. It absorbs ink beautifully, making it one of the best t shirt materials for beginners who want vibrant, opaque prints. Ringspun and combed cotton feel extra smooth and are popular for retail-style POD brands.

Quick tip: Cotton prints look great but may shrink if washed hot. Always pre-shrink blanks or note wash instructions for customers.

Polyester

Polyester is a synthetic fiber prized for durability. It dries quickly, resists wrinkles, and holds color well without fading. Many polyester garments today use recycled polyester (rPET), made from plastic bottles, which reduces emissions and appeals to eco-conscious buyers.

But here’s the catch: polyester is less breathable than cotton, and without added elastane, it isn’t naturally polyester fabric stretchy.

Blends

Blended fabrics combine the best of both worlds. A 50/50 cotton/poly blend is durable, resists wrinkles, and feels soft without shrinking as much as pure cotton. Premium blends — like triblends (cotton, polyester, rayon) or sueded blends — are often considered the softest t-shirt materials, offering a luxury feel.

- Gildan Heavy Blend Hoodie (50/50 blend): Affordable, durable, and pill-resistant.

- Bella+Canvas Unisex Sueded T-Shirt (52% cotton / 48% poly): Premium softness and retail fit, often highlighted in reviews.

Sustainability Angle

Eco-friendly fabrics are no longer niche. Organic cotton uses up to 91% less water than conventional cotton and avoids harmful pesticides. Sustainable t-shirt materials like recycled polyester (rPET) use 30–50% less energy to produce than virgin polyester. Hemp, bamboo viscose, and TENCEL™ are also breaking into POD catalogs. These materials often print just as well as traditional fabrics while giving your brand a sustainability edge.

Printing Methods Explained

Think of each printing method as a tool in your toolbox. The key isn’t just knowing what exists — it’s knowing when to use it.

Direct-to-Garment (DTG)

DTG is the inkjet printer of the apparel world. It sprays water-based inks directly into fabric fibers, making it ideal for highly detailed, full-color designs on cotton.

- Pros: Excellent detail, photo-quality prints, great for small runs.

- Cons: Works best on cotton; prints on polyester are dull.

Direct-to-Film (DTF)

DTF prints a design onto PET film, then heat-presses it onto fabric.

- Pros: Incredibly versatile, vivid colors, handles dark fabrics, durable.

- Cons: Slightly raised texture, higher equipment costs, can crack after heavy washing.

Note: The difference between DTF and sublimation lies in fabric compatibility. Sublimation only works with polyester, while DTF works across cotton, blends, and more.

Dye Sublimation

So, what is a sublimation printer? Sublimation uses heat to turn ink into gas, bonding it with polyester fibers or poly-coated blanks.

- Pros: Permanent, ultra-vibrant prints that never crack or peel. Perfect for mugs, puzzles, and all-over prints.

- Cons: Only works on polyester or poly-coated items, and only on light colors.

Screen Printing

The old-school method: ink pushed through stencils (screens) onto fabric.

- Pros: Bold, durable, cost-effective for bulk.

- Cons: Setup is slow and labor-intensive; not efficient for one-offs.

Heat Transfer (Vinyl & Transfer Paper)

A heat press applies vinyl or printed transfers onto fabric.

- Pros: Low cost to start, works on any fabric, perfect for DIY or very small runs.

- Cons: Thick feel, can peel over time, labor heavy for large orders.

Materials for heat press t-shirt printing can range from vinyl sheets and transfer paper to specialty t-shirt press materials for more advanced runs.

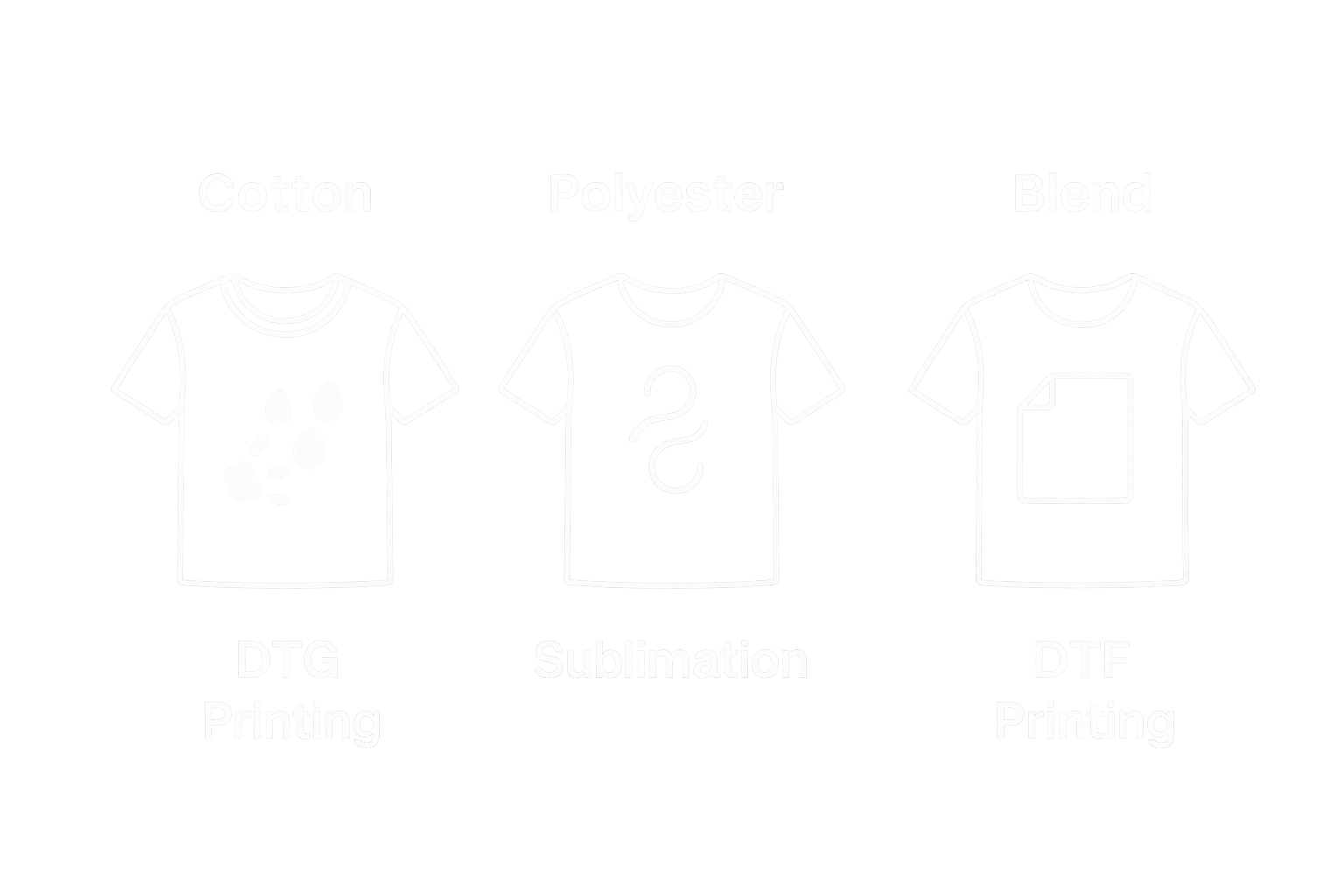

Matching Fabrics with Printing Methods

This is where most beginners stumble. Pairing the wrong fabric with the wrong method almost guarantees poor reviews.

- Sublimation → Polyester (65%+): For sportswear, puzzles, mugs, and other coated products.

- DTF → Cotton, blends, polyester: The Swiss Army knife of POD.

- DTG → Cotton: Best for detail-heavy designs.

- Screen Printing → Cotton or blends: Perfect for bulk merch drops.

- Heat Transfer → Any fabric: Flexible but less durable.

Specialty callout: print on demand puzzles must have a sublimation coating to hold vibrant prints.

Cost and Profitability of Different Methods

Fabric Costs

- Cotton: ~$3.12/kg globally (2024).

- Polyester: ~$2.04/kg, cheaper but less premium.

- Sustainable materials: 1.5–2× more, but consumers pay extra for eco-credibility.

- T shirt raw materials in India are often cheaper than Western suppliers, but shipping raises costs.

Printing Method Costs

- DTG: $5k–$20k equipment, high per-shirt cost, but scalable for custom orders.

- DTF: $1.5k–$2k equipment; works with cheap blanks, good balance.

- Sublimation: ~$300–$600 printer, cheap consumables, limited to poly items.

- Screen Printing: High setup, low per-unit cost in bulk.

- Heat Transfer: Entry-level cost is minimal, but labor isn’t scalable.

Example profit margin:

- Cotton blank $5 + DTG print $4 = $9 cost → $20 retail → $11 profit.

- Premium triblend blank $7 + DTG print $5 = $12 cost → $30 retail → $18 profit.

Pro tip: Always include a bill of materials for t shirt products. Factor in blanks, ink, labor, shipping, and platform fees so your profit margins stay healthy.

Common Mistakes to Avoid

- Sublimation on cotton → colors vanish after one wash.

- DTG on polyester → faded and dull.

- Confusing design vs. printing materials. Fonts and graphics aren’t the same as blanks and inks.

- Skipping test samples. Never scale without testing — it’s cheaper to waste one blank than 50.

- Ignoring BOM (bill of materials). Forgetting shipping or fees shrinks your profit margin.

- Keyword confusion. Example: “his dark materials t-shirt” is about a TV show, not POD.

Author’s hint: If you’re unsure, test two fabrics with the same design and compare. Your future customers will thank you.

Conclusion

At its core, POD success is about nailing the details. The design grabs attention, but the right material and method earn loyalty. Cotton, polyester, blends, DTG, DTF, sublimation — each has its place.

Don’t guess which one works. Test it. Order samples, push the limits with sustainable fabrics, and refine until your products stand out in a crowded market.

Because the POD businesses that thrive aren’t the ones with the flashiest designs. They’re the ones that get the fundamentals right.

FAQ

Q: What’s the difference between DTG, DTF, and sublimation printing?

- DTG → Best for cotton, detailed and soft prints.

- DTF → Works on almost any fabric, vibrant and versatile.

- Sublimation → For polyester/coated items only, permanent results.

Q: What are the best t-shirt materials for POD beginners?

100% cotton and cotton/poly blends are beginner-friendly and easy to source.

Q: Can I print on recycled or sustainable fabrics?

Yes — organic cotton with DTG, rPET polyester with sublimation, and blends with DTF.

Q: What materials do I need for DIY t-shirt printing?

Blank shirts, ink/transfer paper or vinyl, and a heat press. These are the basic t-shirt printing materials you’ll need for small runs.

Q: Which POD products require sublimation coatings?

Mugs, puzzles, ornaments, and other hard goods.

Level Up With PrintCube!

Simply use PrintCube for print on demand. Get started for free. No credit card or subscription required.

Sign Me Up!